联网型风机盘管控制器_风机盘管联网温控器如何连接

1.联网型风机盘管的控制原理

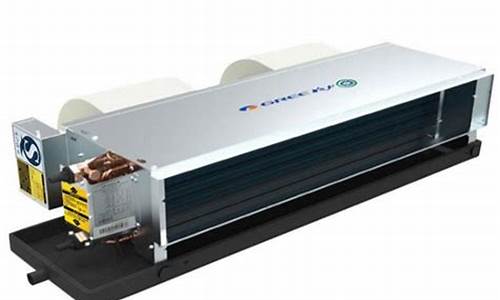

HFCF是特灵公司新一代的环保节能型风机盘管,用最新的低噪声控制技术,最新开发的波纹式亲水膜翅片以及先进的制造

工艺。具有一系列的优点:

低噪

用最新设计的低转速前倾多翼

宽叶轮离心式风机,叶轮经动、

静平衡校正,运行平稳。

分离电容型电机配以永久润滑封

闭轴承,转动平滑、高效。

消声效果良好的保温材料和精巧

的箱体结构设计进一步保证了机

组的超低噪音。

控制独到

机组可配合特灵新型TM50液晶温

控器Trane ICS系统相容。TM50

温控器具有二通阀连锁、节能模式、

联网群控等一系列独特的控制选项

和功能,满足不同场合的控制需求。

安装维护方便

超薄机身,机组高度仅为230mm,节省安装

空间。

结构设计独特,方便现场盘管安装、变向以及

风机叶轮的维护。同时可提供预装的水阀,省

工省时,大大减少水阀漏水的可能性。

独有的排水阀设计,便于客户排空盘管内的存

水,防止冬季盘管冻裂。

直流调速(选项)

直流无刷电机DCBL与传统的AC电机相比,无

论在效率、超低速噪音、节能等各方面均具有

巨大优势。

在实际使用中,机组控制器可以根据室内温度

和设定温度之间的偏差进行PID计算,无级调

节风量,控温精准的同时大大降低能耗和噪音。

高效

盘管用最新研制的波纹式亲水

膜翅片,换热高效的同时,提高

防飞水和防腐能力。

运用先进的机械涨管工艺,加强

铜管与翅片接触的紧密度。

配合超宽叶轮使换热更加充分,

使单位输入功率制冷量超过国内

外同类机组的水准。

型号齐全

9个型号, 覆盖

200~2400CMH

风量。产品型号

更加齐全、分档

更加合理,更好

的满足客户的需求。

保温绝热

用一次冲压成

型的整体式凝结

水盘,避免泄漏,

杜绝补丁。

保温经过特殊设

计和加工, 更趋

完善。无需在水

盘上使用镙钉固

定, 防止水盘锈

蚀的可能。

2

控制可选件控制说明

液晶温控器TM50

特灵数码出风口TDG( 线控或遥控)

机械温控器TM60 水阀WCV

选项

2管制

4管制

DCBL TDG UV

控制

联网型风机盘管的控制原理

1 Summary

1.1 INTRODUCTION

With the constant development of China's economy, a high degree of information-based society, the new high-tech technology lied to all aspects of making intelligent has become a development trend. Tend to be intelligent automation system equipment from the start. In this paper, we present for the graduation project "intelligent small central air-conditioning," explained PLC control of Intelligent Design and central air-conditioning (Freezing Point) systems.

1.2 system and process Introduction

Is introduced as follows: We he this in the design, there are two central air-conditioning system, cooling water pump from the Big Three, three chilled water pump, a cooling tower fan, two chiller comprising two sets of major equipment such as refrigeration system (due to system Small, large power cooling towers, laboratories, etc., the system of the usual two sets of refrigeration system different from the two chiller only choose a cooling tower, roved by the calculation, this does not affect their performance) is one chiller Complete sets of equipment manufacturing plant supply. According to this design laboratory requirements, we selected the five full-2 * closed compressor chiller. It is based on general principles and laws of the air-conditioning, such as automatic control by the microprocessor. Chiller from the compressor, condenser and evaporator components. Compression of the refrigerant compressors, compressed into the refrigerator condenser, cooling water cooling, a liquid, precipitation heat away from the cooling water and cooling Tarja discharged into the atmosphere. Liquid refrigerant from the condenser into the evaporator evaporation absorb heat, chilled water cooling and chilled water fan coil absorbed into the cold air in the heat. This cycle of it, to bring out the indoor heat to reach the objective of reducing the ambient temperature. Therefore, the central air-conditioning refrigeration system for process control requirements:

(1) for the measurement of chilled water flow and return water temperature, thus calculate the actual air-conditioning cooling load, according to the actual cooling load chiller to determine the number of Taiwan Open, the best energy-sing status.

(2) the procedures for equipment linked: Start: cooling tower fan - cooling water pump - chilled water pumps - chiller. Stop: chiller - chilled water pumps - cooling water pump - the cooling tower fan. When one of the cooling water pump / chilled water pump failure, the backup cooling water pump / chilled water pump will automatically enter the workforce.

(3) measurement system for chilled water pipes to the pressure △ P = P1-P2 control of their bypass valve (TV) openings, to maintain the pressure.

(4) because we designed this lab aims to give students a more vivid image of the study and understanding of central air-conditioning system, so the design process, we will take into account the ropriate and important position to facilitate the installation of observation refrigeration Agent or the peep-flow situation.

1.3 PLC theory and lication

Central air-conditioning refrigeration system control are three kinds of control: the early relay control systems, direct digital controller DDC and the PLC (PLC) control system. Relay control system because of the high failure rate, the system complicated, the obvious shortcomings of higher power has been gradually eliminated by the people, direct digital controller DDC Although there he been very intelligent in the development. However, due to DDC its own anti-jamming capability and step-by-step grade structure and the limitations of limiting the scope of its lication. On the contrary, PLC control system with its reliable operation, use and maintenance are very convenient and anti-interference capability and high-speed network for the new structure of these significant advantages to gradually wide range of lications.

PLC is a computer in a family. In the last century after the invention of being, in machine tools, various lines of transportation machinery, power generation, chemical, and electronics industries of electrical control equipment has been widely used, early PLC, known as Programmable logic controller (Programmable Logic Controller), that is referred to as the PLC.

PLC is a powerful, reliable, easy maintenance, and so many advantages. The traditional relay circuit, it is difficult to achieve complex logic functions and the digital control, but also to achieve a certain amount of logic control not only the design cumbersome and difficult to upgrade and prone to failure, maintenance complex, now has been great Medium-control equipment abandoned by the system. The PLC is being widely used and he been gradually replaced the relay circuit logic control. With the leap in science and technology development, PLC also has been continuously improved and strong, while its functions and greatly exceeded the scope of control logic, such as communication and networking functions, such as self-diagnosis. So today we he such a device known as programmable logic controller, but we still referred to such devices used for PLC.

ZigBee联网型风机盘管智能温控器用国际最先进的微电脑测量控制芯片和ZigBee无线自组网物联技术,内置多种节能控制策略,自动感知周围环境,自动调控中央空调风机盘管运行,保持室内恒温;自动记录风机盘管各风速档运行时间,用于空调主机系统能耗分户计量;用户操作简单,系统管控灵活方便,节能效果明显,广泛应用于各种中央空调系统末端风机盘管分户计量与节能控制。

(2420223263@qq)

声明:本站所有文章资源内容,如无特殊说明或标注,均为采集网络资源。如若本站内容侵犯了原著者的合法权益,可联系本站删除。